![]()

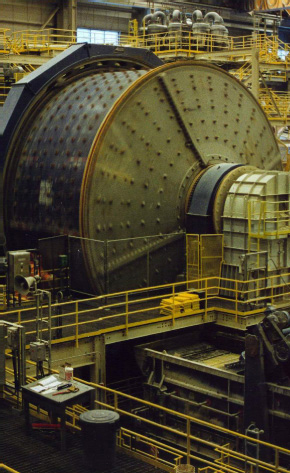

Scrap is melted and refined in two 35 fan electric arc furnaces.

The steel is poured into a ladie and into copper molds to form a semi-finished product called billets.

The billet size used for grinding balls is 5.25” x 5.25”.

The billets are heated up in a furnace to a temperature around 2100F and then forged into balls and passed through and rounder. The balls are cooled down by passing through some drums.

The smooth round bars are heated up to a temperature above the re-crystalization temperature and then quenched in water to obtain the desired hardness. The balls are then tempered in a furnace to relieve stress caused by the quenching process. This is the final step before the balls are shipped.